Are you confident the battery you pick will keep your small off‑grid system running reliably without costing you more time and money than necessary?

How To Choose The Right Battery Type For A Small Off‑Grid System

7 Battery Mistakes That Kill Off‑Grid Power Systems (and How to Avoid Them)

This guide helps you choose a battery that fits your needs, budget, and installation constraints. You’ll get clear comparisons, sizing guidance, safety tips, maintenance steps, and the seven most common mistakes that ruin systems — with practical fixes so you don’t repeat them.

Why battery choice matters for a small off‑grid system

Your battery is the heart of an off‑grid setup. It stores generation from solar, wind, or other charging sources and supplies power when generation is absent. The wrong battery can lead to poor performance, frequent replacements, safety risks, and higher lifetime costs. You’ll save money and headaches when you match battery chemistry, capacity, and management to how you actually use energy.

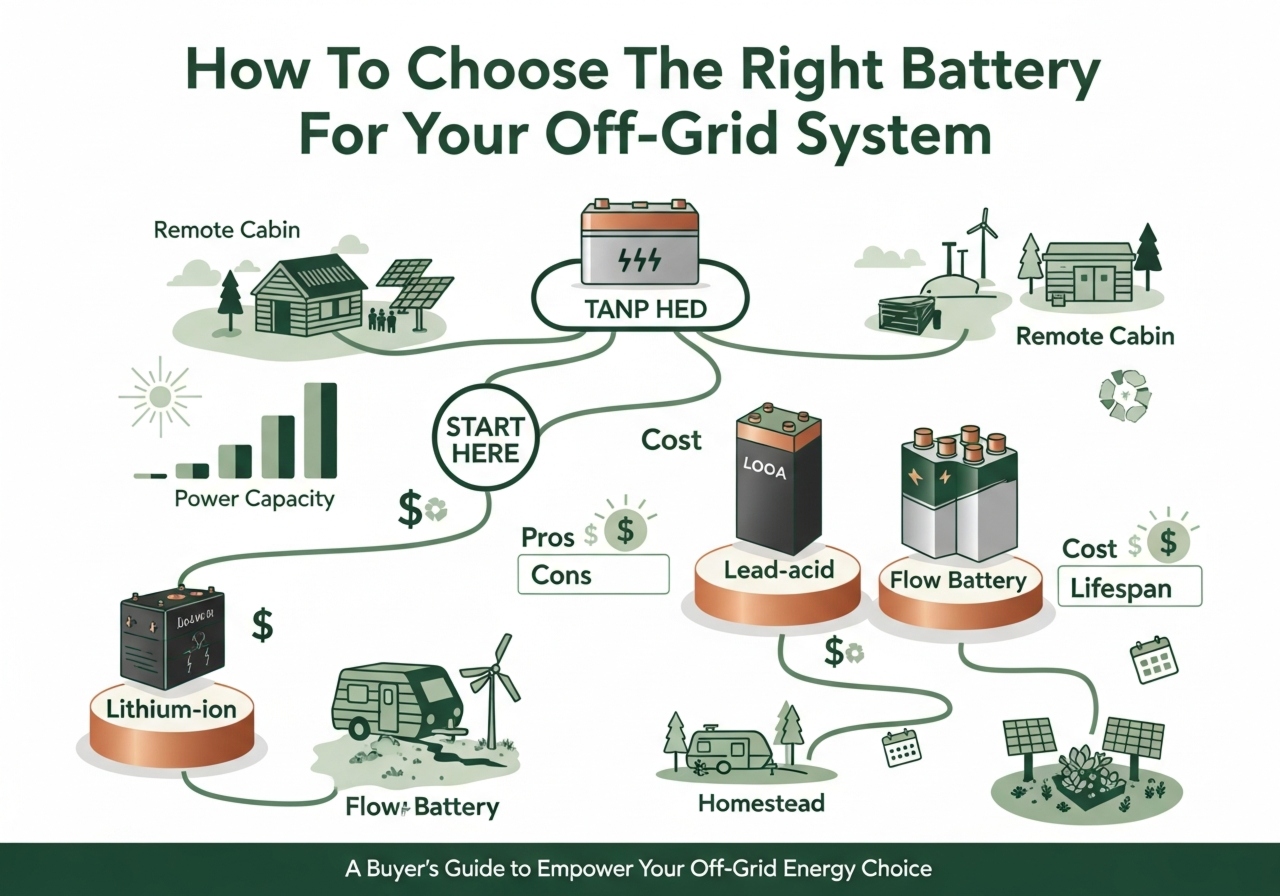

Quick overview of battery chemistries

You should first understand the common battery types for small off‑grid systems and what each offers. Each chemistry has strengths and trade‑offs in cost, cycle life, weight, maintenance, and required charging profile.

Main battery types

- Flooded Lead‑Acid (FLA): Traditional, economical, requires maintenance and ventilation. Good if you can perform regular maintenance and want lowest upfront cost.

- Sealed Lead‑Acid (SLA) — AGM and Gel: Maintenance‑free and safer indoors, but shorter cycle life and heavier per kWh than lithium.

- Lithium Iron Phosphate (LiFePO4): Lighter, long cycle life, high efficiency, fast charging, and usable depth of discharge. Higher upfront cost but lower total cost of ownership for many users.

- Other lithium chemistries (NMC, LCO): Rare for small off‑grid due to safety and cost; mostly used in EVs and consumer electronics.

Comparison table: core characteristics

| Characteristic | Flooded Lead‑Acid (FLA) | AGM (SLA) | Gel (SLA) | LiFePO4 (Lithium) |

|---|---|---|---|---|

| Upfront cost per kWh | Low | Moderate | Moderate | High |

| Cycle life (typical) | 300–800 | 400–900 | 400–900 | 2,000–5,000+ |

| Depth of Discharge (usable) | 30–50% recommended | 50% | 50% | 80–90% |

| Efficiency (round trip) | 70–85% | 80–85% | 80–85% | 90–98% |

| Maintenance | High (water, equalization) | Low | Low | Very low (BMS) |

| Weight per kWh | Heavy | Heavy | Heavy | Light |

| Temperature tolerance | Poor cold/heat | Moderate | Moderate | Broad (but needs management) |

| Ventilation needed | Yes | Minimal | Minimal | No |

| Safety (thermal runaway risk) | Low (but hydrogen risk) | Low | Low | Low (LiFePO4 safest of lithiums) |

| Recycling / disposal | Established | Established | Established | Emerging infrastructure |

Use this table as a starting point when comparing options for your specific constraints.

How to match battery type to your priorities

You’ll want to pick the battery that aligns with your budget, maintenance willingness, weight/space constraints, and expected years of service.

If budget is your primary concern

Flooded lead‑acid gives the lowest initial cost per kWh. You must perform regular maintenance (water top‑ups, equalization) and allow ventilation. For short‑term or seasonal use where you can maintain batteries, this is often appropriate.

If you want low maintenance and indoor installation

AGM or Gel batteries let you install indoors without venting. They’re more forgiving than flooded batteries but have shorter lifespans and lower usable capacity than lithium.

If you want long life, high efficiency, and weight savings

LiFePO4 is typically the best long‑term value for a small off‑grid system when you can afford the higher initial cost. It delivers high cycle life, deep usable depth of discharge, and fast charging with high efficiency.

If you need the simplest, safest option for people unfamiliar with battery care

A lithium pack with a good Battery Management System (BMS) will minimize user tasks while providing predictable performance. You must still ensure correct charging hardware and safe installation.

Sizing your battery bank: capacity and power

Choosing the right capacity avoids overcycling or insufficient power when you need it most. You’ll calculate energy needs, account for inefficiencies and depth of discharge, and pick a system voltage.

Step 1 Calculate daily energy consumption

List devices and average hours used per day. Multiply watts × hours to get watt‑hours (Wh). Sum all loads to get total daily Wh.

Example:

- LED lighting: 50 W × 5 h = 250 Wh

- Refrigerator (efficient DC): 60 W average × 8 h = 480 Wh

- Phone charging: 10 W × 2 h = 20 Wh Total = 750 Wh/day

Step 2 Decide days of autonomy

You’ll decide how many cloudy or no‑generation days you want the battery to cover. For small systems, 1–3 days is typical. Multiply daily Wh by days of autonomy.

Step 3 Account for battery usable capacity and efficiency

Divide required Wh by usable fraction of battery capacity (Depth of Discharge) and by round‑trip efficiency.

Example with LiFePO4 (80% usable, 95% efficiency) and 2 days autonomy: Required energy = 750 Wh × 2 = 1,500 Wh Battery capacity needed = 1,500 / (0.8 × 0.95) ≈ 1,974 Wh ≈ 2 kWh nominal

For a lead‑acid bank (50% usable, 80% efficiency): Battery capacity needed = 1,500 / (0.5 × 0.8) = 3,750 Wh ≈ 3.75 kWh nominal

Step 4 Choose system voltage

You’ll pick 12V, 24V, or 48V systems based on inverter size and wiring losses.

- 12V: Common for very small systems under a few hundred watts, easy to source batteries but higher current and thicker wires.

- 24V: Middle ground for moderate loads.

- 48V: Better for larger small systems (inverters >1,500 W) to reduce current and wiring costs. Higher voltage reduces conductor size and improves efficiency for larger loads. Select a battery configuration (series/parallel) to reach the system voltage and capacity.

Sizing table example: required nominal battery capacity

| Daily load (Wh) | Days autonomy | Chemistry | Usable DoD | Efficiency | Nominal capacity (Wh) |

|---|---|---|---|---|---|

| 1,000 | 2 | LiFePO4 | 80% | 95% | 1,316 |

| 1,000 | 2 | Lead‑acid (SLA) | 50% | 80% | 2,500 |

| 2,000 | 3 | LiFePO4 | 80% | 95% | 7,895 |

| 2,000 | 3 | Flooded | 40% | 75% | 17,778 |

These numbers illustrate why lithium can be significantly smaller for the same usable energy.

Charging hardware and correct charge profiles

Batteries require the right charging profile to get long life. You’ll match the charge controller and inverter/charger settings to your battery chemistry.

MPPT vs PWM charge controllers

- MPPT (Maximum Power Point Tracking): More efficient, especially when solar panel voltage is higher than battery voltage. Recommended for most small off‑grid systems.

- PWM (Pulse Width Modulation): Simpler and cheaper, best when panel voltage closely matches battery voltage and you have small arrays.

Charge stages and settings

Lead‑acid charging typically uses bulk, absorption, and float stages. Flooded batteries also require periodic equalization. Lithium batteries usually need bulk and float or a tailored algorithm; many lithium systems use absorption very briefly or skip it entirely. You must set charging voltages for temperature compensation where applicable. Using a controller with configurable voltages or one specified for LiFePO4 is essential.

Battery Management System (BMS)

Lithium batteries require a BMS to protect cell balance, over/under voltage, overcurrent, and temperature. Some lithium batteries include integrated BMS; others require external solutions. Make sure your inverter/charger communicates with the battery or at least respects its charge limits.

Installation and wiring best practices

Safe wiring and correct fusing will prevent fires and preserve battery life.

Series and parallel configurations

You’ll wire cells or batteries in series to increase voltage, and in parallel to increase capacity. Avoid mixing old and new batteries or different brands in the same series/parallel string. If batteries are arranged in series, ensure each unit is matched in capacity, age, and state of charge.

Wiring gauge, fuses, and disconnects

Choose wire gauge based on maximum continuous current and distance to minimize voltage drop. Fuse each battery string at the battery positive to protect against short circuits. Install a DC disconnect between the battery bank and inverter/charger for safe work.

Ventilation and location

Place flooded batteries in a ventilated area due to hydrogen during charging. Sealed batteries and lithium batteries need no ventilation but should be kept in a dry, temperature‑stable location. Avoid placing batteries in uninsulated sheds where temperatures swing widely.

Temperature considerations

Batteries perform poorly and age faster at high temperatures and lose capacity at low temperatures. For lithium, most BMS units will prohibit charging below freezing without a battery heater or temperature‑controlled charger. Lead‑acid batteries need temperature compensation in charging voltages.

Maintenance and monitoring

Routine care extends battery life and reduces downtime.

Flooded lead‑acid maintenance

You must check and top up electrolyte levels with distilled water, clean terminals, perform equalization charges periodically, and monitor specific gravity using a hydrometer. Corrosion, loose connections, and acid spills should be addressed immediately.

Sealed lead‑acid maintenance

Minimal maintenance is required, but you should keep terminals clean, check voltage and charging behavior, and ensure correct charger settings.

Lithium maintenance

You’ll mainly monitor state of charge (SoC), BMS alarms, and temperature. Ensure firmware updates for smart inverters/chargers when available.

Monitoring options

Use a battery monitor that measures state of charge, voltage, current, and historical trends. Accurate SoC helps you avoid over‑discharging and lets you shift loads or run a generator at the right time.

Safety and disposal

Batteries contain hazardous materials and must be handled safely.

Safety tips

- Always wear eye and hand protection when working with batteries.

- Keep sparks and flames away from flooded batteries due to hydrogen risk.

- Use insulated tools to avoid shorts.

- Use proper fuses and overcurrent protection.

- Ensure secure mounting to prevent tipping or vibration damage.

End‑of‑life and recycling

Follow local regulations for battery recycling. Lead‑acid recycling infrastructure is mature. Lithium recycling options are improving but check local facilities for proper disposal.

Lifetime cost analysis and decision making

You’ll weigh upfront cost against lifecycle cost, factoring in cycle life, usable capacity, efficiency, maintenance, and replacement frequency.

Simple cost comparison method

Calculate cost per usable kWh over expected life:

- Upfront cost / (usable capacity × cycle life) = cost per cycle‑kWh (rough) Include charger and BMS costs, maintenance labor, and disposal to get a fuller lifecycle cost.

Example:

- Lead‑acid bank: $800 for 3.75 kWh nominal, usable 1.875 kWh, 800 cycles => $800 / (1.875 × 800) ≈ $0.53 per usable kWh

- LiFePO4 bank: $2,400 for 2 kWh nominal, usable 1.6 kWh, 3,000 cycles => $2,400 / (1.6 × 3,000) ≈ $0.50 per usable kWh This simplified example shows lithium can be competitive over time despite higher upfront cost, especially when accounting for lower maintenance and higher efficiency.

7 Battery Mistakes That Kill Off‑Grid Power Systems (and How to Avoid Them)

Below are the most common mistakes you’ll encounter, with practical steps to avoid each one.

1. Choosing the wrong chemistry for your use case

Mistake: Picking a battery based only on lowest upfront cost or convenience without matching it to your expected duty cycle, maintenance ability, and space constraints. How to avoid it: Analyze your daily energy use, days of autonomy, and whether you can maintain flooded batteries. Choose lithium if you want long life and low maintenance; choose flooded if you accept maintenance for lower upfront costs.

2. Under‑sizing the battery bank

Mistake: Buying a bank that looks right on paper for average days but leaves you without power on cloudy days or when usage increases. How to avoid it: Size using realistic worst‑case scenarios, include inefficiencies, and allow at least 1–3 days autonomy for small systems. Use the usable capacity and efficiency numbers for your chosen chemistry to calculate nominal capacity.

3. Improper charging profile or incompatible charger

Mistake: Using a charger or controller with incorrect voltages or charge stages that damage chemistry over time (e.g., failing to stop equalization on sealed batteries, overcharging lithium without BMS). How to avoid it: Verify charge controller/inverter settings are set for your battery type and include temperature compensation where needed. Use MPPT controllers for best solar utilization and a charger designed for lithium if you select that chemistry.

4. Mixing battery types, ages, or sizes

Mistake: Combining old and new batteries, or mixing chemistries in the same bank. This leads to imbalance, early failure, and unpredictable capacity. How to avoid it: Always use identical batteries from the same batch and manufacturer. If you need more capacity, add matched batteries in the same configuration; avoid mixing different technologies.

5. Poor installation and undersized wiring/fuses

Mistake: Using undersized wires, incorrect fusing, or inadequate connections that cause voltage drop, heat, and dangerous conditions. How to avoid it: Calculate wire gauge based on current and distance. Fuse each positive battery connection. Use proper battery terminals, torque to manufacturer specs, and keep wiring neat and protected.

6. Neglecting maintenance for serviceable batteries

Mistake: Letting flooded batteries sit low on water, not performing equalization, or ignoring corrosion until failure. How to avoid it: Set a regular maintenance schedule. Check electrolyte levels monthly, clean terminals, and perform equalization as manufacturer suggests. Monitor specific gravity and voltages regularly.

7. Ignoring temperature effects and poor placement

Mistake: Installing batteries in extreme heat or cold without mitigation, which accelerates degradation or prevents charging. How to avoid it: Choose a sheltered, temperature‑stable location. Use insulation or battery heaters in very cold climates for lithium, and ventilate flooded batteries. Consider relocating batteries or adding climate control for long life.

Troubleshooting common battery problems

You’ll encounter issues; knowing quick checks can save time.

Battery not charging properly

Check solar input, charge controller settings, wiring, and fuses. Verify panel output under load and confirm controller shows proper charging stage. For lithium, check BMS state and temperature lockout.

Rapid voltage drop under load

This often indicates high internal resistance due to aging batteries or sulfation in lead‑acid batteries. Test battery capacity with a load test or get professional assessment.

Batteries swelling or venting

Stop using them immediately and investigate. Swelling suggests severe overcharging or thermal issues — a significant safety risk. Replace the battery and correct charging/ventilation issues.

Uneven state of charge in series strings

This suggests imbalance between cells or batteries. For lead‑acid, perform equalization (if allowed). For lithium, check BMS balancing function. Replace damaged/weak units in the string to restore balance.

Recommended setups for common small off‑grid scenarios

Pick a type and size that matches your actual use.

A: Tiny cabin for weekends (lighting, small fridge, phone charging)

- Daily load: ~1–2 kWh

- Recommendation: 12–24V LiFePO4 1.5–3 kWh bank with MPPT controller and small inverter (1,000–1,500 W). If budget constrained, a well‑maintained flooded lead‑acid bank sized for 2–3 days autonomy.

B: Full‑time tiny home (moderate loads, fridge, water pump)

- Daily load: 4–8 kWh

- Recommendation: 48V LiFePO4 bank for efficiency, 3–6 kWh usable at minimum, MPPT array sized for charging needs, high‑quality inverter/charger with BMS integration.

C: RV weekend use (portable, weight limited)

- Daily load: 0.5–2 kWh

- Recommendation: LiFePO4 portable battery or two 100–200 Ah 12V LiFePO4 cells in parallel for low weight and long service. Use 12V DC loads where possible to avoid inverter losses.

D: Backup system for home essentials

- Daily load: prioritised essentials (fridge, some lighting)

- Recommendation: LiFePO4 bank sized for critical load hours, or SLA bank if used infrequently and budget is tight. Ensure automatic transfer and generator integration if needed.

Questions to ask before you buy

These questions help you narrow choices and specify equipment correctly.

- What is your average and peak daily consumption?

- How many days of autonomy do you want?

- Can you perform maintenance or prefer maintenance‑free?

- Is weight or space a limiting factor?

- What is your budget for upfront cost vs lifetime cost?

- Do you have extreme temperatures where batteries will be stored?

- Does your inverter/charger support the battery chemistry and BMS integration?

Final checklist before installation

Use this checklist to avoid common pitfalls.

- Confirm required usable capacity and battery chemistry.

- Choose system voltage (12/24/48V) based on inverter size and cabling.

- Match charge controller/inverter charging profile to battery.

- Verify BMS compatibility and communication options.

- Calculate wire gauge and fuse sizes; order proper terminals.

- Plan battery location with ventilation, temperature control, and security.

- Set up battery monitoring and alarms.

- Prepare a maintenance schedule if using serviceable batteries.

- Document configuration (series/parallel wiring, serial numbers).

Closing recommendations

You’ll get the best long‑term value by matching battery type to how you live with your off‑grid system. If you want low fuss and long life, lithium (LiFePO4) is often worth the upfront cost. If cost is critical and you can commit to maintenance, flooded lead‑acid can serve well in seasonal or budgeted setups. Carefully size the bank for real usage, use the right charging hardware and settings, and avoid the seven mistakes outlined here. With the right choices, your system will be reliable, safe, and cost‑effective for years.

If you want, tell me your daily loads, preferred days of autonomy, system voltage preference, and budget, and I’ll help calculate a recommended battery bank and equipment list tailored to your small off‑grid system.